Layin Jirgin Ƙasa na Karfe na AREMA, Layin Jirgin Ƙasa Mai Sauƙi

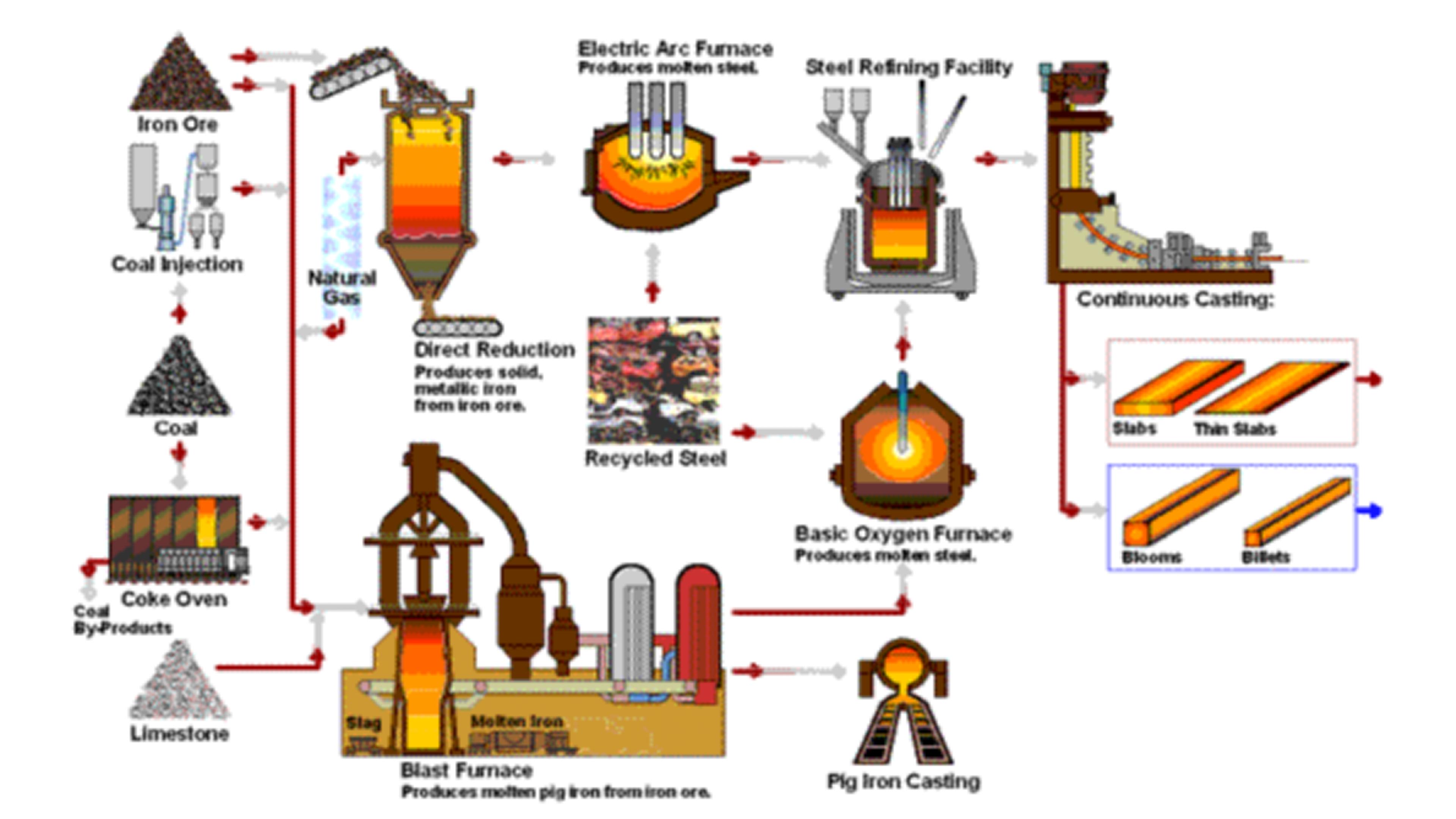

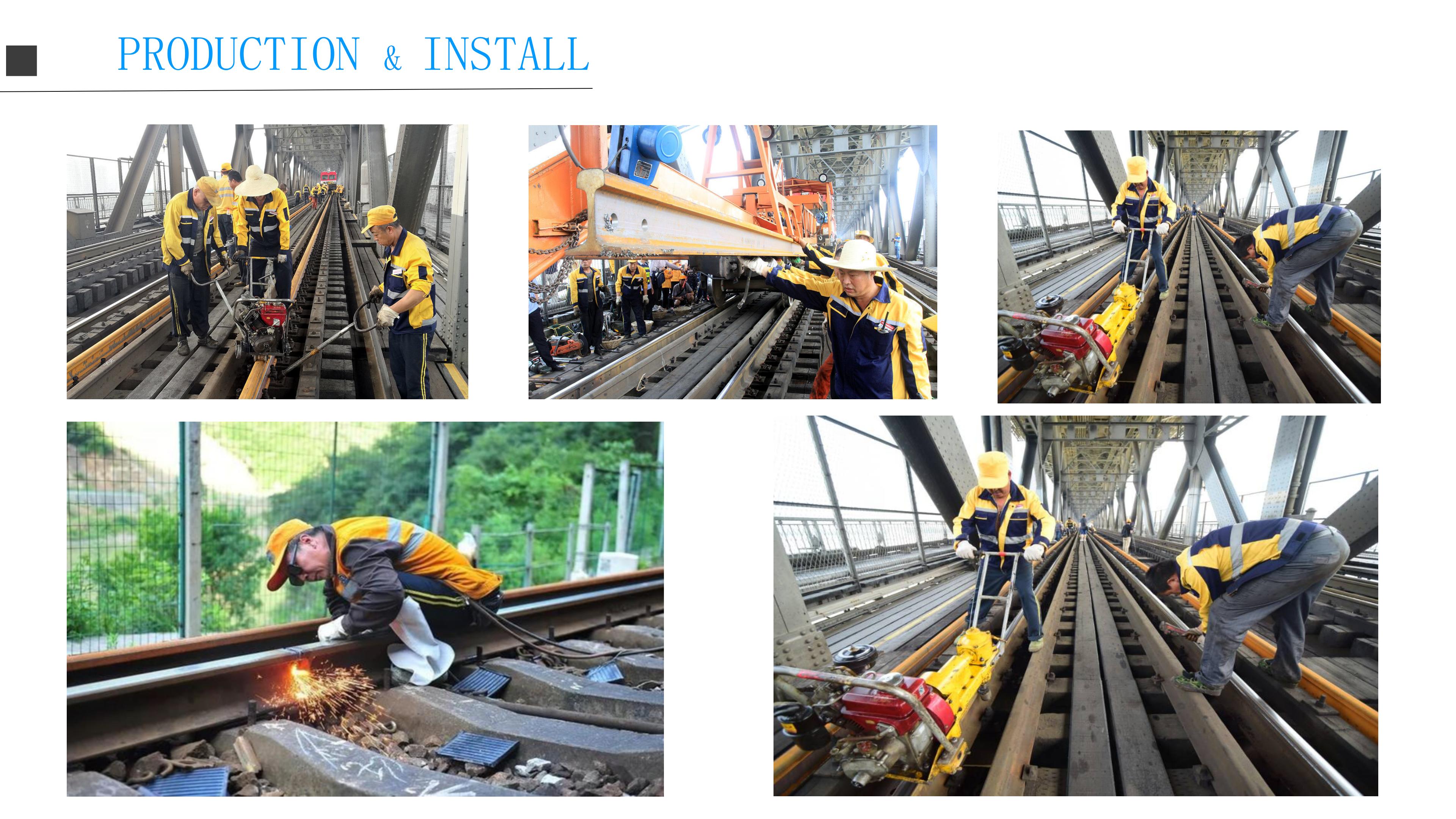

Tsarin Samar da Kayayyaki

Tsarin Fasaha da Gine-gine

Tsarin ginikayayyakin layin dogo na jumlaLayukan sun ƙunshi injiniyanci mai inganci da kuma la'akari da abubuwa daban-daban da kyau. Yana farawa da tsara tsarin layin dogo, la'akari da amfani da aka yi niyya, saurin jirgin ƙasa, da kuma ƙasa. Da zarar an kammala ƙirar, tsarin ginin zai fara da waɗannan muhimman matakai:

1. Hakowa da Tushen Gida: Ma'aikatan ginin suna shirya ƙasa ta hanyar haƙo yankin da kuma ƙirƙirar harsashi mai ƙarfi don tallafawa nauyi da matsin lamba da jiragen ƙasa ke haifarwa.

2. Shigar da Ballast: Ana sanya wani Layer na dutse mai niƙa, wanda aka sani da ballast, a saman da aka shirya. Wannan yana aiki a matsayin Layer mai ɗaukar girgiza, yana samar da kwanciyar hankali, kuma yana taimakawa wajen rarraba nauyin daidai gwargwado.

3. Haɗi da Maƙala: Sannan a sanya ƙugiya ta katako ko siminti a saman ƙugiya, suna kwaikwayon tsarin da ya yi kama da firam. Waɗannan ƙugiya suna ba da tushe mai aminci ga hanyoyin layin dogo na ƙarfe. Ana ɗaure su ta amfani da takamaiman ƙugiya ko maƙulli, don tabbatar da cewa sun kasance a wurinsu.

4. Shigar da Layin Dogo: Layin dogo na ƙarfe mai tsawon mita 10, wanda galibi ake kira da layin dogo na yau da kullun, an shimfida shi da kyau a saman madaurin. Kasancewar an yi su da ƙarfe mai inganci, waɗannan hanyoyin suna da ƙarfi da juriya mai ban mamaki.

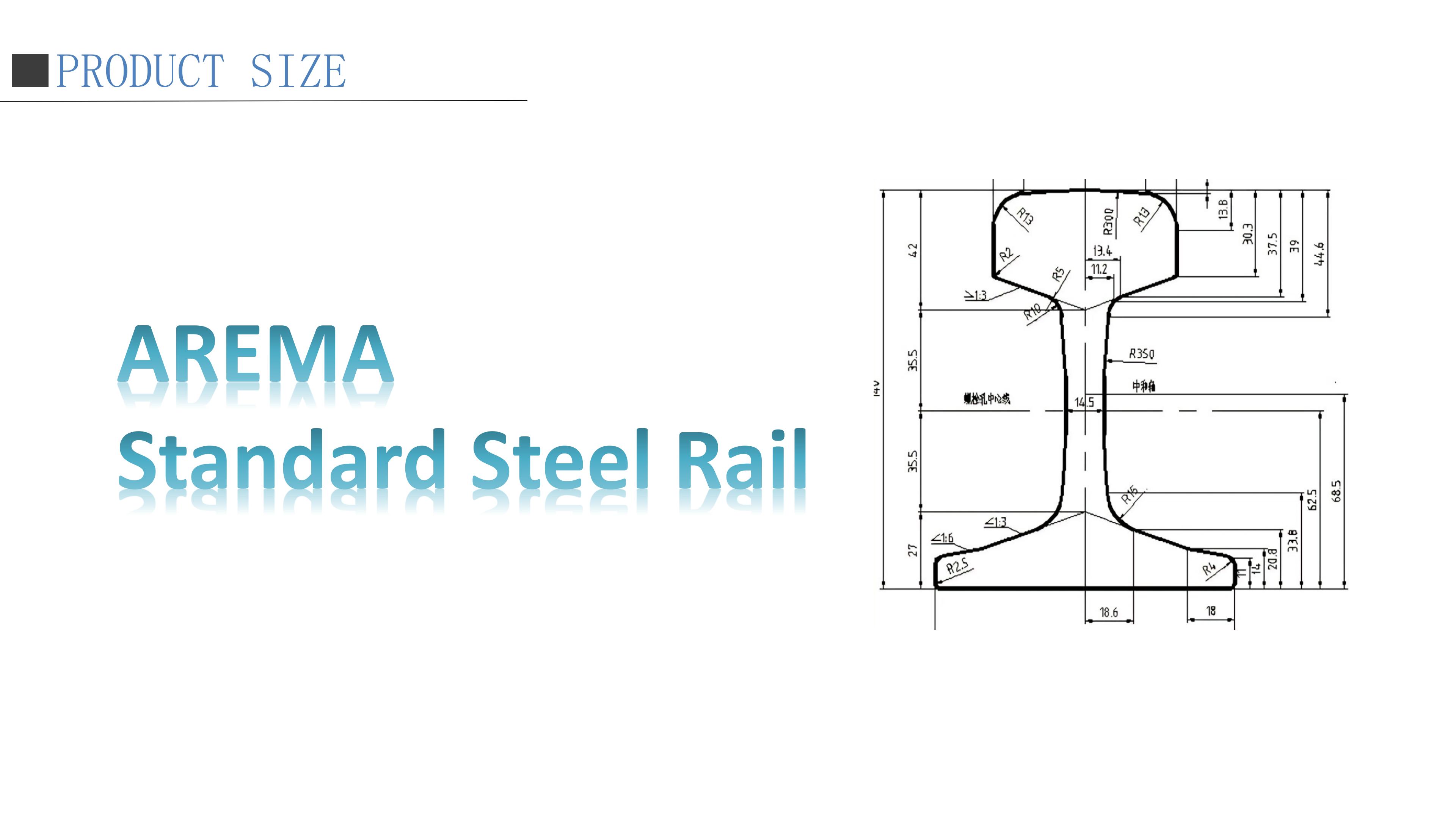

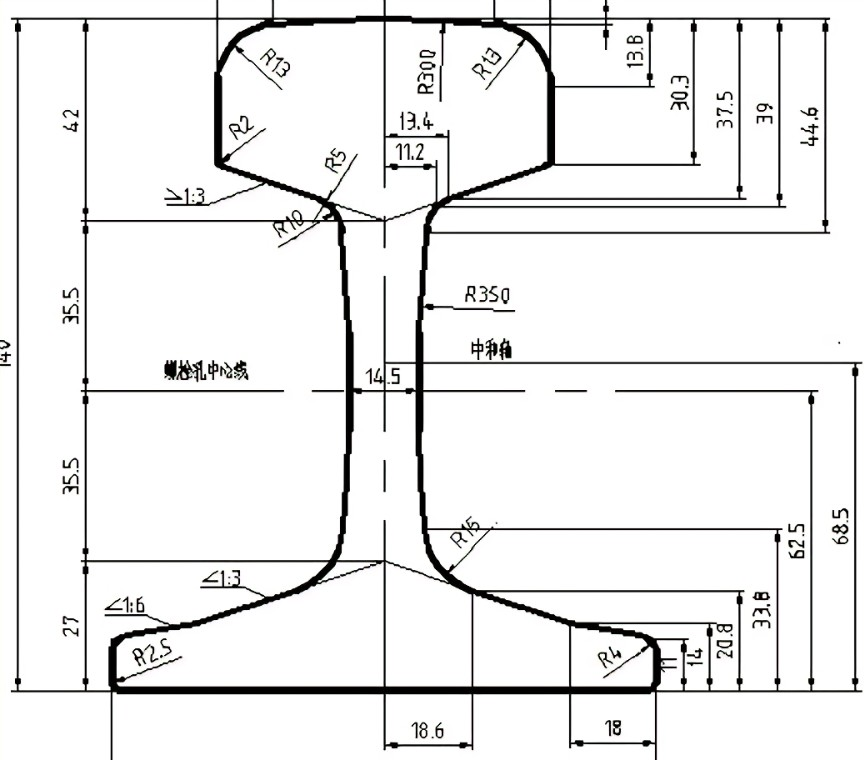

Girman Kayayyaki

| Dogon ƙarfe na yau da kullun na Amurka | |||||||

| samfurin | girma (mm) | abu | ingancin kayan aiki | tsawon | |||

| faɗin kai | tsayi | allon tushe | Zurfin kugu | (kg/m) | (m) | ||

| A(mm) | B(mm) | C(mm) | D(mm) | ||||

| ASCE 25 | 38.1 | 69.85 | 69.85 | 7.54 | 12.4 | 700 | 6-12 |

| ASCE 30 | 42.86 | 79.38 | 79.38 | 8.33 | 14.88 | 700 | 6-12 |

| ASCE 40 | 47.62 | 88.9 | 88.9 | 9.92 | 19.84 | 700 | 6-12 |

| ASCE 60 | 60.32 | 107.95 | 107.95 | 12.3 | 29.76 | 700 | 6-12 |

| ASCE 75 | 62.71 | 122.24 | 22.24 | 13.49 | 37.2 | 900A/110 | 12-25 |

| ASCE 83 | 65.09 | 131.76 | 131.76 | 14.29 | 42.17 | 900A/110 | 12-25 |

| 90RA | 65.09 | 142.88 | 130.18 | 14.29 | 44.65 | 900A/110 | 12-25 |

| 115RE | 69.06 | 168.28 | 139.7 | 15.88 | 56.9 | Q00A/110 | 12-25 |

| 136RE | 74.61 | 185.74 | 152.4 | 17.46 | 67.41 | 900A/110 | 12-25 |

Layin dogo na Amurka:

Bayani dalla-dalla: ASCE25, ASCE30, ASCE40, ASCE60, ASCE75, ASCE85,90RA,115RE,136RE, 175LBs

Daidaitacce: ASTM A1, AREMA

Kayan aiki: 700/900A/1100

Tsawon: mita 6-12, mita 12-25

FA'IDA

layukan ƙarfeyana tallafawa alkiblar jirgin ƙasa, yana haɗa kowace tasha a cikin hanyar sadarwa, yana haɗa birni da ƙauye, kuma waɗannan tashoshin suna haɗa mutane da kayayyaki daga wurare daban-daban zuwa gaba ɗaya, suna samar da hanyar sadarwa mai kyau ta sufuri. Haɗin jirgin ƙasa yana da alaƙa kai tsaye da inganci, tattalin arziki da amincin tsarin jirgin ƙasa gaba ɗaya.

AIKIN

Kamfaninmu'smasu samar da layin dogo na ƙarfeAn jigilar tan 13,800 na layin dogo na ƙarfe da aka fitar zuwa Amurka a tashar jiragen ruwa ta Tianjin a lokaci guda. An kammala aikin ginin tare da shimfida layin dogo na ƙarshe a kan layin jirgin ƙasa. Waɗannan layukan dogo duk sun fito ne daga layin samar da kayayyaki na duniya na masana'antar layin dogo da ƙarfe, suna amfani da Tsarin Duniya zuwa mafi girma da kuma mafi tsaurin ƙa'idojin fasaha.

Don ƙarin bayani game da kayayyakin layin dogo, tuntuɓe mu!

WeChat: +86 13652091506

Lambar waya: +86 13652091506

Imel:[an kare imel]

AIKACE-AIKACE

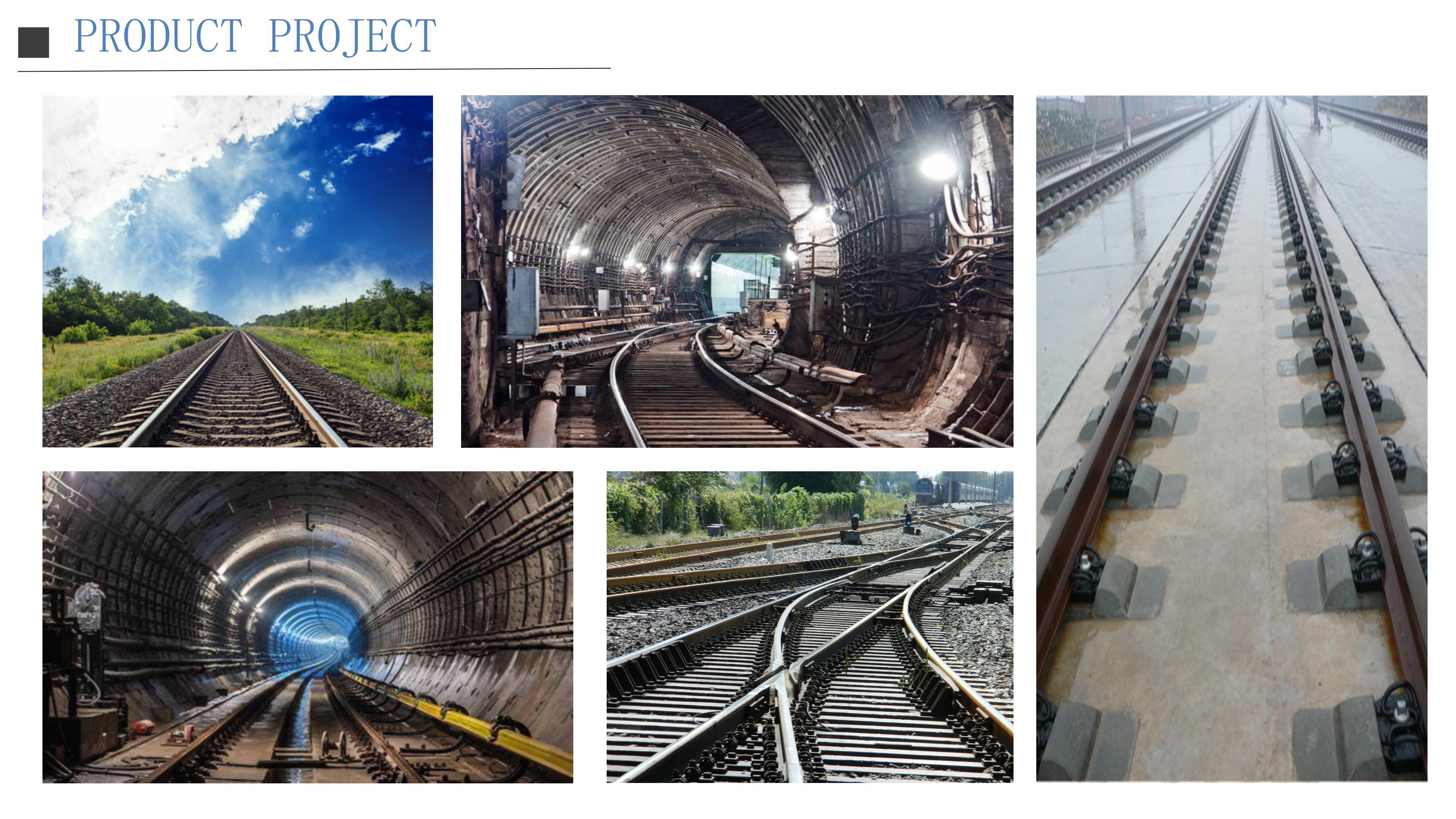

Hanyar Layin Jirgin Ƙasa ta KarfeSufuri ne mai sauri, saurin ya fi girma. Domin tabbatar da daidaiton jirgin ƙasa a cikin tsarin tuƙi mai sauri, da kuma yin aiki mai kyau na sufuri, dole ne jirgin ya cika ƙarfinsa da juriyarsa ga gajiya, domin tabbatar da daidaiton jirgin.

1. Sufurin Jirgin Kasa: Ana amfani da layukan ƙarfe sosai a sufurin jirgin ƙasa, ciki har da jigilar fasinjoji da kaya ta jirgin ƙasa, jiragen ƙasa na ƙarƙashin ƙasa, jiragen ƙasa masu saurin gudu, da sauransu, kuma su ne muhimman abubuwan da ke cikin sufurin jirgin ƙasa.

2. Sabis na Tashar Jiragen Ruwa: Ana amfani da layukan ƙarfe a fannonin jigilar kayayyaki kamar tashoshin jiragen ruwa da yadi a matsayin layukan jigilar kayayyaki don ɗaga kayan aiki, na'urorin sauke kaya, da sauransu don sauƙaƙe lodawa, sauke kaya da motsa kwantena da kaya.

3. Sufurin ma'adinai: Ana iya amfani da layukan ƙarfe a wuraren haƙar ma'adinai da ma'adinai a matsayin kayan jigilar ma'adinai a cikin ma'adanai don sauƙaƙe haƙar ma'adinai da jigilar ma'adanai.

A takaice, a matsayin wani muhimmin sashi a cikin sufuri na jirgin ƙasa, layin dogo yana da fa'idodin ƙarfi mai yawa, juriya ga lalacewa, kwanciyar hankali mai ƙarfi, ingantaccen gini, da ƙarancin kuɗin kulawa. Ana amfani da su sosai a cikin layin dogo, jigilar jiragen ruwa, sufuri na ma'adinai da sauran fannoni.

MAKUNKURI DA JIRGIN SAUYA

1. Sufurin jirgin ƙasa

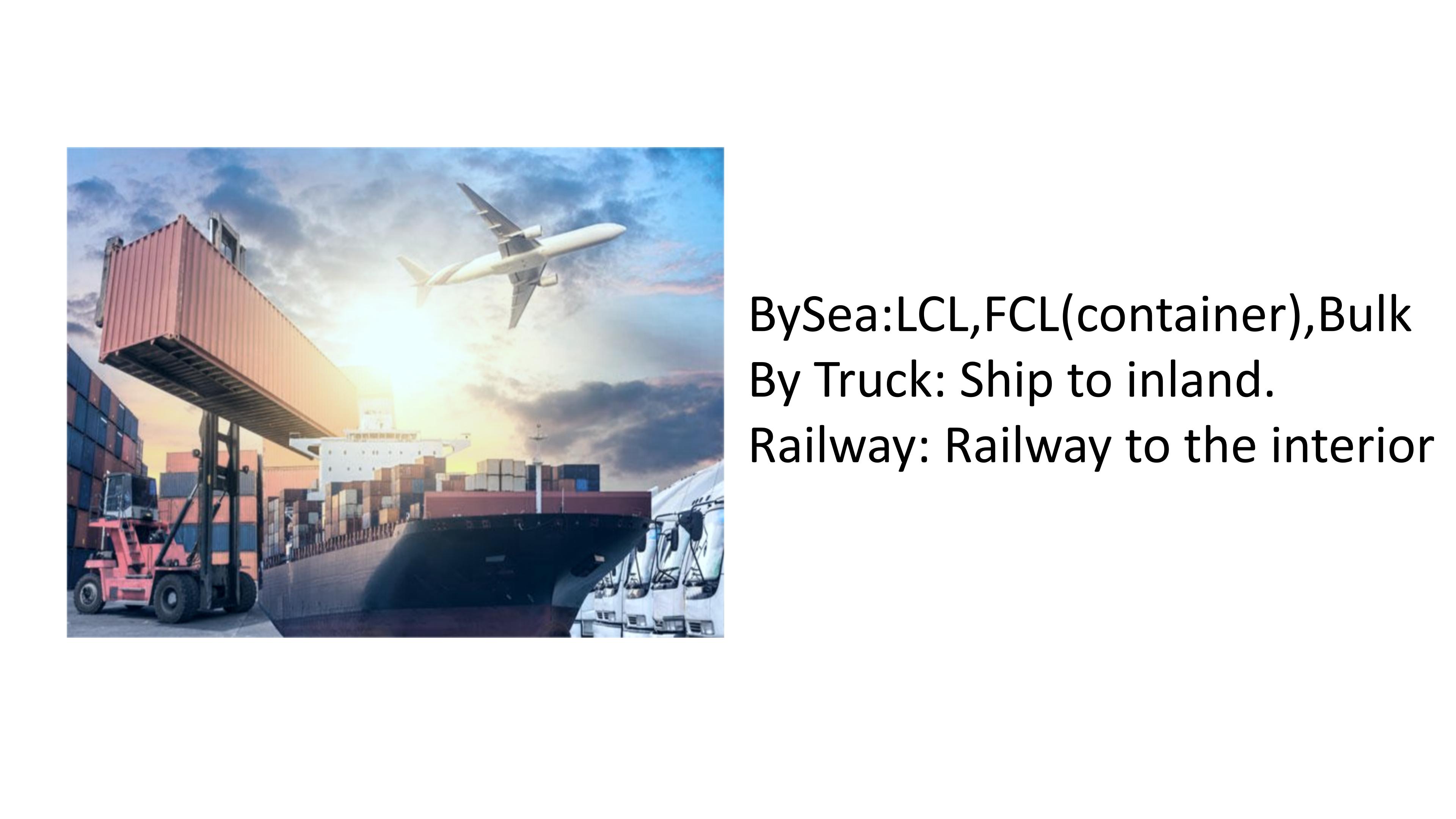

layin ƙarfesuna ɗaya daga cikin kayayyakin da ake amfani da su a sufurin jirgin ƙasa. Sufurin jirgin ƙasa yana da fa'idodin aminci, gudu da ƙarancin farashi. A lokacin sufuri, ya kamata a mai da hankali kan kare layukan dogo daga lalacewa, kuma galibi ana amfani da motocin sufuri na musamman na jirgin ƙasa don sufuri. A lokacin shigarwa, a kula da alkiblar shimfiɗawa da hanyoyin haɗi don guje wa kurakurai da abubuwan ɗan adam ke haifarwa.

2. Sufuri a kan hanya

Sufurin hanya wata hanya ce ta gama gari ta jigilar dogayen layukan dogo kuma tana ɗaya daga cikin hanyoyin da aka saba amfani da su wajen gina ko gyara layukan dogo. A lokacin sufuri, dole ne a ɗauki wasu matakai don tabbatar da cewa kayan ba su zame ko lilo ba, ta haka ne za a guji haɗurra. A lokaci guda, ya kamata a tsara kuma a gudanar da cikakken tsarin sufuri bisa ga tsarin.

3. Sufurin ruwa

Don jigilar dogayen layukan dogo a tsawon nisa, ana amfani da jigilar ruwa gabaɗaya. A cikin jigilar ruwa, ana iya zaɓar jiragen ruwa iri-iri don jigilar kaya, kamar jiragen ruwa na kaya, kwale-kwale, da sauransu. Kafin ɗaukar kaya, ya kamata a yi la'akari da tsawon da nauyin layukan dogo, da kuma ƙarfin ɗaukar kaya da kuma aikin aminci na jirgin don tantance hanyar ɗaukar kaya da adadin da ya dace. Bugu da ƙari, ana buƙatar ɗaukar matakan kariya don guje wa lalacewar da ba ta dace ba ga layukan dogo yayin jigilar ruwa.

Jigilar dogayen layukan dogaye abu ne mai matuƙar muhimmanci a fannin injiniya, kuma ya kamata a kula da jerin takamaiman bayanai na aiki da cikakkun bayanai na kariya don guje wa mummunan sakamako kamar asara da asarar rayuka sakamakon sakaci.

Ƙarfin Kamfani

An yi shi a China, sabis na ajin farko, inganci na zamani, shahara a duniya

1. Tasirin sikelin: Kamfaninmu yana da babban sarkar samar da kayayyaki da kuma babban masana'antar ƙarfe, yana cimma tasirin girma a fannin sufuri da saye, kuma ya zama kamfanin ƙarfe wanda ke haɗa samarwa da ayyuka.

2. Bambancin Samfura: Bambancin Samfura, duk wani ƙarfe da kuke so ana iya siyan sa daga gare mu, galibi yana aiki a cikin tsarin ƙarfe, layukan ƙarfe, tarin takardar ƙarfe, maƙallan photovoltaic, ƙarfe na tashar, coils na silicon da sauran samfura, wanda ke sa ya fi sassauƙa Zaɓi nau'in samfurin da ake so don biyan buƙatu daban-daban.

3. Ingantaccen wadata: Samun layin samarwa mai ƙarfi da sarkar samar da kayayyaki na iya samar da ingantaccen wadata. Wannan yana da mahimmanci musamman ga masu siye waɗanda ke buƙatar adadi mai yawa na ƙarfe.

4. Tasirin alama: Suna da tasiri mafi girma a cikin alamar kasuwanci da kuma kasuwa mafi girma

5. Sabis: Babban kamfanin ƙarfe wanda ke haɗa keɓancewa, sufuri da samarwa

6. Farashin gasa: farashi mai ma'ana

* Aika imel zuwa[an kare imel]don samun ƙiyasin ayyukanku

ZIYARAR KASUWANCI

Tambayoyin da ake yawan yi akai-akai

1. Ta yaya zan iya samun ƙiyasin farashi daga gare ku?

Za ku iya barin mana saƙo, kuma za mu amsa kowane saƙo akan lokaci.

2. Za ku isar da kayan a kan lokaci?

Eh, mun yi alƙawarin samar da kayayyaki mafi inganci da kuma isar da su akan lokaci. Gaskiya ita ce ƙa'idar kamfaninmu.

3. Zan iya samun samfurori kafin oda?

Eh, ba shakka. Yawanci samfuranmu kyauta ne, za mu iya samar da su ta hanyar samfuranku ko zane-zanen fasaha.

4. Menene sharuɗɗan biyan kuɗin ku?

Lokacin biyan kuɗinmu na yau da kullun shine ajiya 30%, kuma sauran ya dogara da B/L. EXW, FOB, CFR, da CIF.

5. Shin kuna karɓar duba na ɓangare na uku?

Eh lallai mun yarda.

6. Ta yaya muke amincewa da kamfanin ku?

Mun ƙware a harkokin kasuwancin ƙarfe tsawon shekaru a matsayinmu na masu samar da zinare, hedikwatarmu tana lardin Tianjin, muna maraba da yin bincike ta kowace hanya, ta kowace hanya.