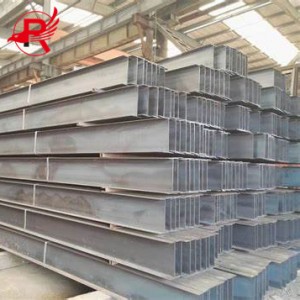

Hasken Karfe Mai Siffar H ASTM | Hasken H Mai Zafi Mai Naɗewa don Ginshiƙan Karfe & Sashe

Hasken ASTM A36 Hwani nau'in katako ne na ƙarfe mai tsari wanda aka yi da ƙarfe mai carbon, wani abu ne da ake amfani da shi sosai kuma mai amfani da shi wanda aka san shi da ƙarfi da dorewarsa. Ana siffanta katakon H da siffar "H" ta musamman, wadda ke ba da kyakkyawan ƙarfin ɗaukar kaya da tallafi a aikace-aikacen gini da injiniya daban-daban. Tare da kyawawan halayensa na tsarin gini, ana amfani da katakon H na carbon a cikin gina gine-gine, gadoji, da sauran ayyukan ababen more rayuwa. Yana ba da mafita mai araha da aminci don ƙirƙirar tsare-tsare masu ƙarfi da juriya, wanda hakan ya sa ya zama zaɓi mai shahara a masana'antar gini. Ƙarfi da ƙarfin walda na ƙarfen carbon suna ƙara haɓaka dacewarsa ga aikace-aikacen gini mai nauyi, wanda hakan ya sa katakon H ya zama zaɓi mafi soyuwa ga injiniyoyi da magina waɗanda ke neman kayan gini masu inganci da dogaro.

Cikakkun bayanai na ƙarfe mai zafi da aka yi birgima da h yawanci ya haɗa da waɗannan bayanai dalla-dalla:

Girma: Girma da girman H-Beam, kamar tsayi, faɗi, da kauri, an ƙayyade su bisa ga buƙatun aikin.

Halayen da suka shafi sassa daban-daban: Muhimman halaye na H-Beam sun haɗa da yankin, lokacin inertia, tsarin sashe, da nauyin kowane raka'a tsawonsa. Waɗannan halaye suna da mahimmanci don ƙididdige ƙirar tsarin da kwanciyar hankali na tarin.

Tsarin Samar da Kayayyaki

1. Shiri na farko: gami da siyan kayan masarufi, duba inganci da shirya kayan aiki. Yawanci ana yin amfani da ƙarfe mai narkewa ne daga injin yin ƙarfe mai inganci na tanderu mai zane-zane ko injin yin ƙarfe na tanderu mai amfani da wutar lantarki, wanda ake samarwa bayan an duba inganci.

2. Narkewa: Zuba ƙarfen da aka narke a cikin abin juyawa sannan a ƙara ƙarfe ko ƙarfen alade da ya dace don yin ƙarfe. A lokacin aikin yin ƙarfe, ana sarrafa yawan carbon da zafin ƙarfen da aka narke ta hanyar daidaita yawan sinadarin graphitizing da kuma hura iskar oxygen a cikin tanderu.

3. Billet ɗin simintin ci gaba: Ana zuba billet ɗin yin ƙarfe a cikin injin simintin ci gaba, kuma ana zuba ruwan da ke gudana daga injin simintin ci gaba a cikin crystallizer, wanda ke ba da damar ƙarfen da aka narke ya taurare a hankali don ya zama billet.

4. Mirgina Mai Zafi: Ana yin birgima mai zafi ta cikin na'urar mirgina mai zafi don ya kai ga girman da aka ƙayyade da siffar geometric.

5. Kammala birgima: An gama birgima billet ɗin da aka yi zafi, kuma girmansa da siffar billet ɗin sun fi daidai ta hanyar daidaita sigogin injin niƙa da kuma sarrafa ƙarfin birgima.

6. Sanyaya: Ana sanyaya ƙarfen da aka gama don rage zafin jiki da kuma gyara girma da kaddarorinsa.

7. Duba inganci da marufi: Duba inganci na kayayyakin da aka gama da marufi bisa ga girma da buƙatun adadi.

Girman Kayayyaki

| Kayayyaki | Hasken H mai zafi da aka yi birgima |

| Wurin Asali | Hebei, China |

| Matsayi | Q235B/SS400/Q355B/S235JR/S355JR |

| Daidaitacce | ASTM / AISI / JIS / EN / DIN |

| Girman | Faɗin Yanar Gizo: 100-912mm |

| Faɗin Flange: 50-302mm | |

| Kauri a Yanar Gizo: 5-18mm | |

| Kauri na Flange: 7-34mm | |

| Alloy Ko A'a | Ba Alloy ba |

| Fasaha | naɗewa mai sanyi ko zafi |

| Sabis na Sarrafawa | Lanƙwasawa, Walda, Hudawa, Yankewa |

| Lokacin Isarwa | Kwanaki 31-45 |

| Tsawon | 1-12m |

| Rasidin kuɗi | ta hanyar nauyin ka'ida |

| Aikace-aikace | tsarin gini da tsarin injiniya |

| Biyan kuɗi | T/T; |

| Girman Hasken H | ||||

| Faɗin Yanar Gizo (mm) | Faɗin Flange (mm) | Kauri a Yanar Gizo (mm) | Kauri na Flange (mm) | Nauyin Ka'ida (kg/m) |

| 100 | 50 | 5 | 7 | 9.54 |

| 100 | 100 | 6 | 8 | 17.2 |

| 125 | 60 | 6 | 8 | 13.3 |

| 125 | 125 | 6.5 | 9 | 23.8 |

| 150 | 75 | 5 | 7 | 14.3 |

| 148 | 100 | 6 | 9 | 21.4 |

| 150 | 150 | 7 | 10 | 31.9 |

| 175 | 90 | 5 | 8 | 18.2 |

| 175 | 175 | 7.5 | 11 | 40.4 |

| 194 | 150 | 6 | 9 | 31.2 |

| 198 | 99 | 4.5 | 7 | 18.5 |

| 200 | 100 | 5.5 | 8 | 21.7 |

| 200 | 200 | 8 | 12 | 50.5 |

| 200 | 204 | 12 | 12 | 56.7 |

| 244 | 175 | 7 | 11 | 44.1 |

| 248 | 124 | 5 | 8 | 25.8 |

| 250 | 125 | 6 | 9 | 29.7 |

| 250 | 250 | 9 | 14 | 72.4 |

| 250 | 255 | 14 | 14 | 82.2 |

| 294 | 200 | 8 | 12 | 57.3 |

| 294 | 302 | 12 | 12 | 85 |

| 298 | 149 | 5.5 | 8 | 32.6 |

| 300 | 150 | 6.5 | 9 | 37.3 |

| 300 | 300 | 10 | 15 | 94.5 |

| 300 | 305 | 15 | 15 | 106 |

| 340 | 250 | 9 | 14 | 79.7 |

| 344 | 348 | 10 | 16 | 115 |

| 346 | 174 | 6 | 9 | 41.8 |

| 350 | 175 | 7 | 11 | 50 |

| 350 | 350 | 12 | 19 | 137 |

| 388 | 402 | 15 | 15 | 141 |

| 390 | 300 | 10 | 16 | 107 |

| 394 | 398 | 11 | 18 | 147 |

| 396 | 199 | 7 | 11 | 56.7 |

| 400 | 200 | 8 | 13 | 66 |

| 400 | 400 | 13 | 21 | 172 |

| 400 | 408 | 21 | 21 | 197 |

| 414 | 405 | 18 | 28 | 233 |

| 428 | 407 | 20 | 35 | 284 |

| 440 | 300 | 11 | 18 | 124 |

| 446 | 199 | 8 | 12 | 66.7 |

| 450 | 200 | 9 | 14 | 76.5 |

| 458 | 417 | 30 | 50 | 415 |

| 482 | 300 | 11 | 15 | 115 |

| 488 | 300 | 11 | 18 | 129 |

| 496 | 199 | 9 | 14 | 79.5 |

| 498 | 432 | 45 | 70 | 605 |

| 500 | 200 | 10 | 16 | 89.6 |

| 506 | 201 | 11 | 19 | 103 |

| 582 | 300 | 12 | 17 | 137 |

| 588 | 300 | 12 | 20 | 151 |

| 594 | 302 | 14 | 23 | 175 |

| 596 | 199 | 10 | 15 | 95.1 |

| 600 | 200 | 11 | 17 | 106 |

| 606 | 201 | 12 | 20 | 120 |

| 692 | 300 | 13 | 20 | 166 |

| 700 | 300 | 12 | 24 | 185 |

| 792 | 300 | 14 | 22 | 191 |

| 800 | 300 | 14 | 26 | 210 |

| 890 | 299 | 15 | 23 | 213 |

| 900 | 300 | 16 | 28 | 243 |

| 912 | 302 | 18 | 34 | 286 |

FA'IDA

Wasu siffofi da halaye na ƙarfen carbonHasken ASTM A370 H:

- Ƙarfi da ɗorewa: An san ƙarfen carbon da ƙarfi da juriya, wanda hakan ke sa katakon H su iya ɗaukar nauyi mai yawa da kuma samar da kwanciyar hankali a tsarin.

- Nau'i Mai Yawa: Gilashin H da aka yi da ƙarfen carbon suna da amfani mai yawa kuma ana iya amfani da su a cikin ayyukan gini iri-iri, gami da firam ɗin gini, gadoji, da sauran gine-gine.

- Ingancin ƙarfin ɗaukar kaya: Siffar H ta musamman ta katako tana ba da ƙarfin ɗaukar kaya mai inganci, wanda hakan ya sa ya dace da tallafawa nau'ikan gine-gine daban-daban.

- Tattalin arziki:Hasken ASTM A572 Hbayar da mafita mai araha ga ayyukan gini da gini saboda samuwar kayan da kuma araha.

- Mai iya walda: Ana iya walda ƙarfen carbon cikin sauƙi, wanda ke ba da damar ƙera katakon H na musamman don biyan buƙatun aikin.

AIKIN

Kamfaninmu yana da shekaru da yawa na gogewa a fannin cinikin H-beams na ƙasashen waje. Jimlar adadin H-beams da aka fitar zuwa Kanada a wannan karon ya fi tan miliyan 8. Abokin ciniki zai duba kayayyakin a masana'antar. Da zarar kayan sun wuce binciken, za a biya kuɗi kuma a jigilar su. Tun lokacin da aka fara gina wannan aikin, kamfaninmu ya tsara tsarin samarwa a hankali kuma ya tattara tsarin aiwatarwa don tabbatar da isar da aikin ƙarfe mai siffar H akan lokaci. Tunda ana amfani da shi a manyan gine-ginen masana'antu, buƙatun aiki na samfuran ƙarfe mai siffar H sun fi juriya ga tsatsa na dandamalin mai na ƙarfe mai siffar H. Saboda haka, kamfaninmu yana farawa daga tushen samarwa kuma yana ƙara sarrafa yin ƙarfe, ci gaba da siminti da hanyoyin da suka shafi birgima. Ƙarfafa ingancin samfuran takamaiman bayanai daban-daban don a sarrafa su yadda ya kamata a kowane fanni, yana tabbatar da ƙimar wucewa 100% na samfuran da aka gama. A ƙarshe, abokan ciniki sun amince da ingancin sarrafa ƙarfe mai siffar H gaba ɗaya, kuma an cimma haɗin gwiwa na dogon lokaci da fa'idar juna bisa ga amincewar juna.

DUBA KAYAYYAKI

Ga talakawaHasken ASTM A6 H, idan abun da ke cikin carbon ya kasance daga 0.4% zuwa 0.7%, kuma buƙatun kayan aikin injiniya ba su da yawa, ana iya amfani da daidaita yanayin zafi na ƙarshe. Da farko, ana buƙatar samar da ginshiƙan ƙarfe masu siffar giciye. Bayan rarraba aiki a masana'anta, sai a haɗa su, a daidaita su, sannan a duba su don tabbatar da cewa samfuran sun cancanta sannan a kai su yankin gini don haɗawa. A lokacin aikin haɗawa, dole ne a gudanar da haɗawar bisa ga hanyoyin da suka dace. , Ta wannan hanyar ne kawai za a iya tabbatar da ingancin samfurin yadda ya kamata. Bayan an gama haɗawar, dole ne a duba sakamakon shigarwa na ƙarshe. Bayan dubawa, dole ne a yi amfani da raƙuman ultrasonic don gudanar da binciken ciki mara lalata, don a iya kawar da lahani da aka haifar yayin haɗuwa yadda ya kamata. Bugu da ƙari, ana buƙatar sarrafa ginshiƙi mai giciye. A lokacin shigar da tsarin ƙarfe, da farko kuna buƙatar zaɓar bayanin da aka saba, rufe raga don sarrafawa, sannan a yi auna tsaye na tsayin saman ginshiƙi. Bayan haka, ana buƙatar a sarrafa matsar saman ginshiƙi da tsarin ƙarfe don super-deflection, sannan a sarrafa sakamakon super-lebur da sakamakon dubawa na ginshiƙi na ƙasa gaba ɗaya. Ana buƙatar aiwatar da sarrafa ƙafafu masu kauri bayan an tantance matsayin ginshiƙin ƙarfe. Ta hanyar nazarin bayanan sarrafawa, ana sake gyara tsayin ginshiƙin ƙarfe. Bayan an kammala shigarwa, ana buƙatar sake duba bayanan aunawa kuma ana buƙatar duba matsalolin walda. Bugu da ƙari, ana buƙatar sake duba rufe wuraren sarrafawa. A ƙarshe, ana buƙatar zana zane-zanen bayanai na gabanin sarrafa ginshiƙin ƙasan ƙarfe.

AIKACE-AIKACE

Ana amfani da sandunan H na ƙarfe masu tsari a fannoni daban-daban na gini da injiniyanci saboda ƙarfinsu, sauƙin amfani da su, da kuma ƙarfin ɗaukar kaya. Wasu aikace-aikacen da aka saba amfani da su na sandunan H na ƙarfe masu tsari sun haɗa da:

1. Gina Gine-gine: Ana amfani da katakon H a matsayin tallafi a gine-gine, ciki har da ginshiƙai, katako, da tallafin rufin. Suna samar da tsari mai ƙarfi ga gine-ginen kasuwanci da na gidaje.

2. Gina gada: Tayoyin H suna da matuƙar muhimmanci wajen gina gadoji, inda ake amfani da su don ɗaukar nauyin benen gada da kuma sauƙaƙe rarraba kaya a fadin ginin.

3. Tsarin masana'antu: H-beams suna taka muhimmiyar rawa wajen tallafawa manyan kayan aiki, injuna, da kayayyakin more rayuwa a cikin cibiyoyin masana'antu kamar masana'antu, rumbunan ajiya, da cibiyoyin rarrabawa.

4. Ayyukan Kayayyakin more rayuwa: Ana amfani da sandunan ƙarfe na H-beams wajen gina ayyukan ababen more rayuwa kamar manyan hanyoyi, layin dogo, da ramuka, inda ƙarfin ɗaukar nauyinsu yake da mahimmanci don tallafawa manyan wurare da manyan kaya.

5. Rike bango da tara: Ana amfani da sandunan H a matsayin abubuwan asali a cikin tsare bango da tsarin tara bango, suna samar da kwanciyar hankali da tallafi ga riƙe ƙasa da daidaita ta.

6. Aikace-aikacen gine-gine: Baya ga amfani da tsarin su, ana kuma amfani da katakon H a cikin zane-zanen gine-gine don ƙirƙirar abubuwan gani na musamman, kamar katakon da aka fallasa da fasalulluka na kyau a cikin ginin zamani.

MAKUNKURI DA JIRGIN SAUYA

Marufi:

A tattara tarin takardar a amince: A shiryaHasken ASTM A992 Ha cikin tsari mai kyau da kwanciyar hankali, tabbatar da cewa an daidaita su yadda ya kamata don hana duk wani rashin kwanciyar hankali. Yi amfani da madauri ko madauri don ɗaure tarin kuma hana canzawa yayin jigilar kaya.

Yi amfani da kayan kariya na marufi: A naɗe tarin takardu da kayan da ba sa jure da danshi, kamar filastik ko takarda mai hana ruwa shiga, don kare su daga fuskantar ruwa, danshi, da sauran abubuwan muhalli. Wannan zai taimaka wajen hana tsatsa da tsatsa.

Jigilar kaya:

Zaɓi hanyar sufuri mai dacewa: Dangane da yawan da nauyin tarin takardu, zaɓi hanyar sufuri mai dacewa, kamar manyan motoci masu faɗi, kwantena, ko jiragen ruwa. Yi la'akari da abubuwa kamar nisan, lokaci, farashi, da duk wani buƙatun ƙa'ida don sufuri.

Yi amfani da kayan ɗagawa masu dacewa: Don lodawa da sauke tarin takardar ƙarfe mai siffar U, yi amfani da kayan ɗagawa masu dacewa kamar cranes, forklifts, ko lodawa. Tabbatar cewa kayan aikin da ake amfani da su suna da isasshen ƙarfin da za su iya ɗaukar nauyin tarin takardar lafiya.

A tabbatar da nauyin: A ɗaure tarin takardu da aka shirya a kan abin hawa ta amfani da madauri, abin ƙarfafa gwiwa, ko wasu hanyoyi masu dacewa don hana juyawa, zamewa, ko faɗuwa yayin jigilar kaya.

Ƙarfin Kamfani

An yi shi a China, sabis na ajin farko, inganci na zamani, shahara a duniya

1. Tasirin sikelin: Kamfaninmu yana da babban sarkar samar da kayayyaki da kuma babban masana'antar ƙarfe, yana cimma tasirin girma a fannin sufuri da saye, kuma ya zama kamfanin ƙarfe wanda ke haɗa samarwa da ayyuka.

2. Bambancin Samfura: Bambancin Samfura, duk wani ƙarfe da kuke so ana iya siyan sa daga gare mu, galibi yana aiki a cikin tsarin ƙarfe, layukan ƙarfe, tarin takardar ƙarfe, maƙallan photovoltaic, ƙarfe na tashar, coils na silicon da sauran samfura, wanda ke sa ya fi sassauƙa Zaɓi nau'in samfurin da ake so don biyan buƙatu daban-daban.

3. Ingantaccen wadata: Samun layin samarwa mai ƙarfi da sarkar samar da kayayyaki na iya samar da ingantaccen wadata. Wannan yana da mahimmanci musamman ga masu siye waɗanda ke buƙatar adadi mai yawa na ƙarfe.

4. Tasirin alama: Suna da tasiri mafi girma a cikin alamar kasuwanci da kuma kasuwa mafi girma

5. Sabis: Babban kamfanin ƙarfe wanda ke haɗa keɓancewa, sufuri da samarwa

6. Farashin gasa: farashi mai ma'ana

* Aika imel zuwa[an kare imel]don samun ƙiyasin ayyukanku

Tambayoyin da ake yawan yi akai-akai

1. Ta yaya zan iya samun ƙiyasin farashi daga gare ku?

Za ku iya barin mana saƙo, kuma za mu amsa kowane saƙo akan lokaci.

2. Za ku isar da kayan a kan lokaci?

Eh, mun yi alƙawarin samar da kayayyaki mafi inganci da kuma isar da su akan lokaci. Gaskiya ita ce ƙa'idar kamfaninmu.

3. Zan iya samun samfurori kafin oda?

Eh, ba shakka. Yawanci samfuranmu kyauta ne, za mu iya samar da su ta hanyar samfuranku ko zane-zanen fasaha.

4. Menene sharuɗɗan biyan kuɗin ku?

Lokacin biyan kuɗinmu na yau da kullun shine ajiya 30%, kuma sauran ya dogara da B/L.

5. Shin kuna karɓar duba na ɓangare na uku?

Eh lallai mun yarda.

6. Ta yaya muke amincewa da kamfanin ku?

Mun ƙware a harkokin kasuwancin ƙarfe tsawon shekaru a matsayinmu na masu samar da zinare, hedikwatarmu tana lardin Tianjin, muna maraba da yin bincike ta kowace hanya, ta kowace hanya.