Sarrafa Karfe & Musamman

-

Matakalar Karfe ta Waje Tsarin Matakalar Zamani na Karfe don Waje

Matakalar zamani ta waje mai karkace, nau'in matattakala ce mai adana sarari, ta zamani kuma mai aiki, wadda ke juyawa sama a kusa da ginshiƙi na tsakiya. Ana iya amfani da ita a kan baranda, bene, baranda, lambuna, ko kuma a matsayin hanyar haɗi tsakanin sarari a matakai daban-daban.

-

Tsarin ASTM na Musamman na H-Beam ƙera Karfe Mai Tsari don Gine-gine & Tsarin Karfe

Sassan H-Beam sune samfuran ƙarfe na H-beam waɗanda ake sarrafawa ta hanyar yankewa, walda, haƙa rami, gyaran saman ƙasa da sauransu. Ana amfani da su sosai a tsarin ƙarfe, masana'antar masana'antu, wurin aiki, rumbun ajiya, gada da kayayyakin more rayuwa tare da ɗaukar kaya mai yawa da kwanciyar hankali na tsarin.

-

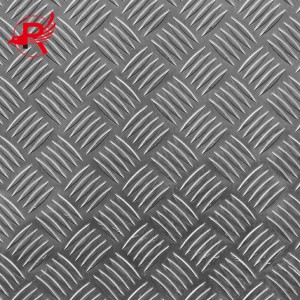

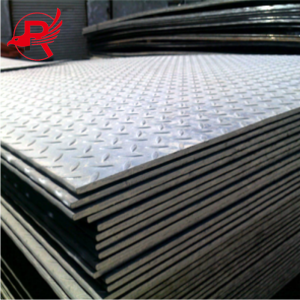

ASTM A36 1008 4320 SS400 S235JR Farantin da aka yi da ƙarfe mai kauri / takardar lu'u-lu'u mai kyau na MS Carbon Karfe

Faranti masu ɗorewa masu lanƙwasa tare da tsare-tsare masu ɗagawa don riƙewa mai kyau—ya dace da aminci ga benaye na masana'antu, hanyoyin tafiya, da matakala.

-

Farantin Karfe Mai Zafi Mai Inganci Mai Tsabtace Fitarwa Mai Daidaita Kaya Mai Hana Zamewa Ga Kaya Don Bene

Faranti masu ɗorewa na ƙarfe masu lanƙwasa tare da tsarin hana zamewa—sun dace da aminci ga benaye na masana'antu, hanyoyin tafiya, da matakala.

-

Farantin Karfe na Astm A36 A252 Carbon Q235 mai kauri

Karfe mai siffar lu'u-lu'u wani nau'in zanen ƙarfe ne mai siffar lu'u-lu'u ko layi a samansa, wanda aka ƙera don ƙara ƙarfin riƙewa da jan hankali. Ana amfani da shi sosai don bene na masana'antu, hanyoyin tafiya, matakala, da sauran aikace-aikace inda juriyar zamewa take da mahimmanci. Ana iya yin waɗannan faranti na ƙarfe da ƙarfe mai kauri, bakin ƙarfe, ko wasu ƙarfe, suna ba da damar yin amfani da su da dorewa ga wurare daban-daban na masana'antu da kasuwanci.

-

Babban Ingancin Masana'antu na Carbon Karfe Faranti Mai Zafi Mai Birgima Faranti Mai Zafi S235 S275 S355 Takardar Karfe ta Carbon Don Ginawa

Faranti na ƙarfe masu lanƙwasa, waɗanda aka fi sani da faranti na ƙarfe masu tsari ko faranti na ƙarfe marasa zamewa, su ne zanen ƙarfe masu tsari mai ɗagawa a saman su. Tsarin da aka saba gani sun haɗa da siffofi na lu'u-lu'u, murabba'i, da zagaye. Waɗannan tsare-tsaren ba wai kawai suna ƙara wa farantin ƙarfen kyau ba, har ma suna ba da kyawun gani da ƙarin ƙarfi. Irin waɗannan faranti na ƙarfe ana amfani da su sosai a dandamalin masana'antu, matattakalar hawa, hanyoyin tafiya, benayen abin hawa, benayen ajiya, da sauran wurare, suna ba da aminci da dorewa.

-

Carbon Karfe Chequered Plate 4 Mm Carbon Karfe Formed Metal Sheet For Building Material

Faranti na ƙarfe masu lanƙwasa, waɗanda aka fi sani da faranti na ƙarfe masu tsari ko faranti na ƙarfe marasa zamewa, su ne zanen ƙarfe masu tsari na yau da kullun na tsage-tsage a saman su. Tsarin gama gari sun haɗa da siffofi na lu'u-lu'u, oval, da zagaye. Wannan tsarin saman na musamman ba wai kawai yana ƙara gogayya da hana zamewa ba, har ma yana ba da wani kyakkyawan salo.

-

Gina Faranti Mai Zafi na Faranti na Checkered ASTM A36 Q235B Q345B S235JR S355JR Faranti Masu Zafi na Karfe

Faranti na ƙarfe masu lanƙwasa, waɗanda aka fi sani da faranti na lu'u-lu'u ko faranti na tattaka, samfuran ƙarfe ne na musamman waɗanda aka ƙera da tsarin saman da aka ɗaga—musamman siffofi na lu'u-lu'u ko layi—wanda aka ƙirƙira ta hanyar birgima mai zafi, sanyaya sanyi, ko kuma yin embossing. Babban fa'idarsu tana cikin aikin hana zamewa na waɗannan laushin da aka ɗaga: ta hanyar ƙara gogayya a saman, suna rage haɗarin zamewa yadda ya kamata ko da a cikin yanayi mai danshi, mai, ko ƙura, wanda hakan ya sa suka zama zaɓi mai da hankali kan aminci don yanayi mai cunkoso ko mai nauyi.

-

OEM Na Musamman Tsarin Matsewa Kayan Aiki Sabis na Kayan Karfe na Karfe ƙera Karfe

Sassan da aka sarrafa na ƙarfe, waɗanda kuma aka sani da sassan ƙarfe da aka ƙera, suna nufin sassa ko samfuran da aka gama da aka yi da kayan ƙarfe (kamar faranti na ƙarfe, bututu, da siffofi na tsari) ta hanyar hanyoyin kamar yankewa, tambari, lanƙwasawa, walda, injina, maganin zafi, da kammala saman, don biyan takamaiman siffa, girma, da buƙatun aiki. Yawanci ana amfani da su azaman mahimman abubuwan kayan aiki, injina, ko tsarin injiniya.

-

Injin Yankan Laser Die Fiber Laser Injin Yankan Laser Sheet Metal

ƙarfe mai yanke laserwata hanya ce ta sarrafa yankewa mai inganci da inganci wadda ake amfani da ita sosai wajen sarrafa karafa, robobi, itace da sauran kayayyaki. Yanke Laser yana amfani da hasken laser mai ƙarfi da ƙarfi don narkewa ko tururi kayan, wanda ke ba da damar yankewa cikin sauri da daidaito. Wannan hanyar sarrafawa tana da halaye masu zuwa:

Da farko dai, yanke laser yana da matuƙar daidaito da kuma daidaito, wanda ke ba da damar yankewa da sassaka kayan aiki masu kyau, kuma ya dace da yin sassa masu siffofi masu rikitarwa da kuma tsari mai kyau.

Na biyu, yanke laser yana da sauri kuma yana da ingantaccen aiki. Kayan aikin yanke laser na iya motsawa da yankewa da sauri, wanda hakan ya sa ya dace da samar da kayayyaki masu yawa da kuma sarrafa su yadda ya kamata.

Bugu da ƙari, yanke laser ba shi da tasiri sosai ga kayan kuma yankin da zafi ke shafa ƙarami ne. Idan aka kwatanta da hanyoyin yankewa na gargajiya, yanke laser na iya rage nakasa da tasirin zafi da kuma kiyaye ainihin halayen kayan.

Yanke Laser ya dace da nau'ikan kayayyaki iri-iri, ciki har da ƙarfe, robobi, gilashi, yumbu, da sauransu, don haka ana amfani da shi sosai a fannin sararin samaniya, kera motoci, kayan lantarki da sauran masana'antu.

A takaice, yanke laser, a matsayin hanyar sarrafa yankewa mai inganci da inganci, yana samar da mafita na sarrafa daidaito ga dukkan fannoni na rayuwa kuma ya zama ɗaya daga cikin mahimman matakai a masana'antar zamani.

-

Sabis na Yankewa da Sarrafa Takardar Karfe na Musamman

Walda tsari ne na gama gari da ake amfani da shi wajen haɗa kayan ƙarfe ko filastik wuri ɗaya ta hanyar narkewa, ƙarfafawa ko matse su wuri ɗaya. Ana amfani da hanyoyin walda a fannin ƙera sassan gini, bututu, tasoshin ruwa da sauran kayayyaki, da kuma a fannin gyara da gyara.

-

Kayan Yanke Ruwa na Ruwa mara Tsami OEM na Musamman Sassan Yankan Karfe na Carbon Bakin Karfe 3/4/5 Injin CNC na Axis

Yanke Waterjet wata fasaha ce ta yanke sanyi mai zurfi wadda ke amfani da magudanar ruwa mai matsin lamba (yawanci ana matsa ta zuwa 30,000–90,000 psi) - sau da yawa ana haɗa ta da barbashi masu gogewa kamar garnet don kayan aiki masu tauri - don yankewa, siffantawa, ko sassaka nau'ikan kayan aiki iri-iri. A matsayin tsari na sanyi, yana guje wa karkacewar zafi, taurarewar abu, ko canje-canjen sinadarai a cikin kayan da aka yanke, wanda hakan ya sa ya dace da aikace-aikacen da ke da saurin zafi ko kuma daidai. Yana nuna ƙarfin iya aiki, yana iya sarrafa kayan aiki kamar ƙarfe (ƙarfe, aluminum, titanium), dutse, gilashi, yumbu, kayan haɗin kai, har ma da abinci, tare da ikon yanke siffofi masu rikitarwa (misali, tsare-tsare masu rikitarwa, gefuna masu lanƙwasa) da kayan aiki masu kauri (har zuwa santimita goma) yayin da yake riƙe gefuna masu santsi da daidaito mai girma. Ana amfani da shi sosai a masana'antu, ciki har da sararin samaniya (don daidaiton sassan ƙarfe), motoci (don sassa na musamman), gine-gine (don abubuwan ado na dutse/gilashi), da kuma kera (don sarrafa kayan haɗin gwiwa), yanke jet ɗin ruwa shi ma ya shahara saboda kyawun muhallinsa - ba ya haifar da hayaki mai guba ko sharar da ta wuce gona da iri, wanda ya dace da buƙatun samar da kore na zamani.